Fixed Load Machine with EDTC

Fixed-shaft Load Machine per CISPR 25 with EDTC

Fixed-shaft Load Machine per CISPR 25 with EDTC

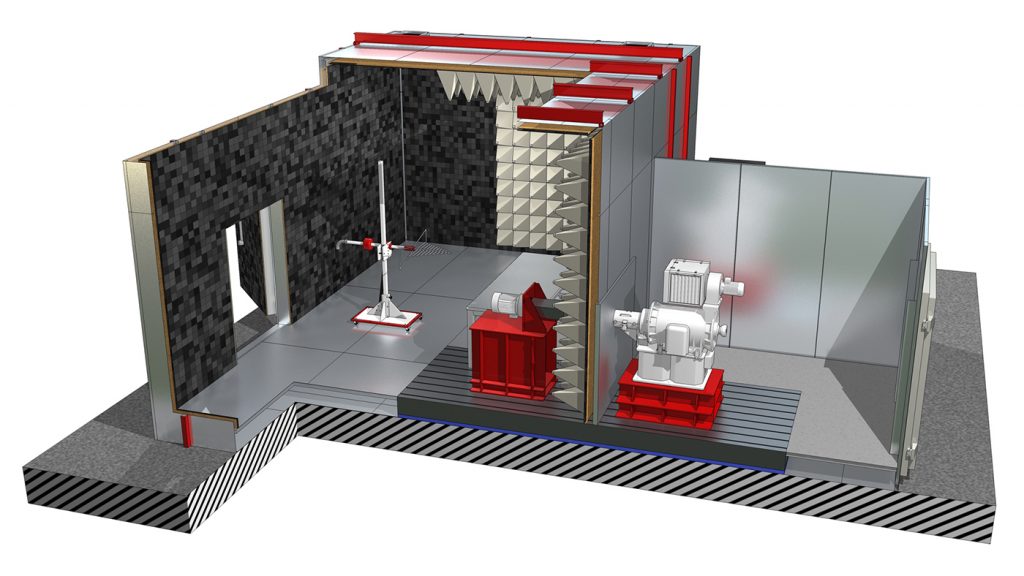

The fixed load machine is fully separated outside the anechoic chamber and provides power to the EUT or receives power coming from the EUT through an isolated and shielded shaft system to ensure a stable test environment for the EUT and secure working. The fixed load machine is available as a complete turnkey system, but also as a modification kit for existing Frankonia chambers.

| Overview |

| Compliance | CISPR 25, ISO 11452 |

| System | Fixed Load Machine (electrical driven) |

| Features | - Useable for motors, components, or in combination with battery tests - Traditional setup - EMC-BlueBox useable as load machine |

| Volume | Table setup in front of wall |

Fully compliant with CISPR 25 Ed.4

Motor adapter and connection to a CISPR 25 test table

Combination with battery tests

Integration to an ACTC chamber (150 kHz to 18/40 GHz)

Vibration-free and non-interacting solid basement (floating slab)

| Version | EDTC-250 | EDTC-350 |

| Power rage | 250 kW | 350 kW |

| Speed max. (HS) | 20.000 1/min. at 500 Nm | 20.000 1/min. at 500 Nm |

| Speed max. (HT) | 3.000 1/min. at 4.500 Nm | 3.000 1/min. at 4.500 Nm |

Emission

CISPR 25

Immunity

ISO 11452

| Chamber Type | EDTC with Fixed-shaft Version | |

| External dimensions | 7.880 x 5.480 x 3.750 mm (LxWxH) | |

| Setup | Table setup | |

| Measuring distances | 1,0 m | |

| Load capacity | up to 10,0 tons | |

| Frequency range | 9 kHz/ 150 kHz to 18 GHz (option 40 GHz) | |

Full compliant emission (EMI) according to CISPR 25 Ed.4

(ALSE verification acc. to the long-wire method recommended)

Full compliant immunity (EMS) according to ISO 11452