ACTC

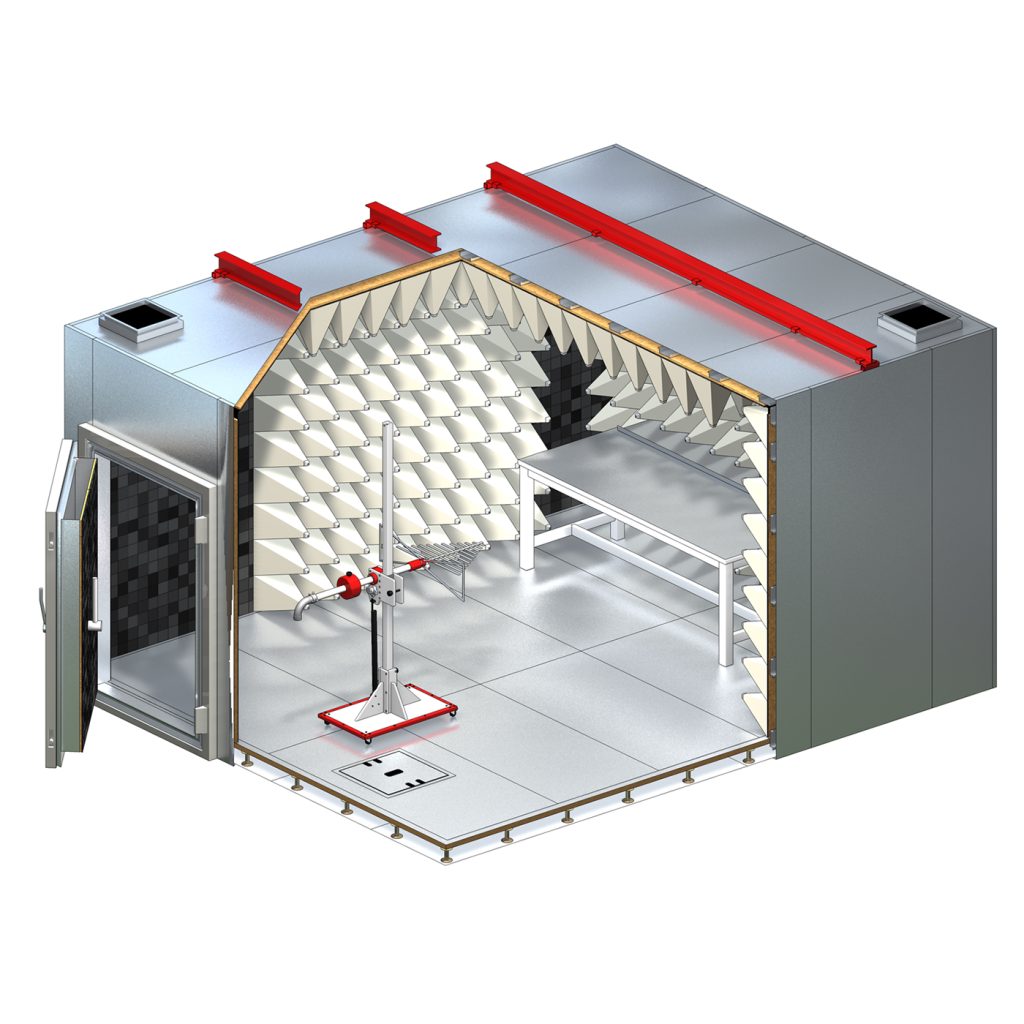

CISPR 25 Automotive Component Testing Chamber

The ACTC is Frankonia’s automotive component testing chamber solution at 1,0 m measuring distance. This chamber solution is adapted for full compliant tests of automotive components according to CISPR 25 and ISO 11452. A permanent plug-in contact strip is installed between the absorbers to ensure the electrical connection of the test table to the shielding and includes the test table as required per to CISPR 25. The typical chamber is lined with ferrite absorbers and partially lined with Frankosorb® hybrid absorbers.

Features

Absorbers

Typical Verification Standards

Emission

Immunity

Typical Specifications

| Chamber Type | ACTC | ACTC L |

| External dimensions | 6.380 x 5.480 x 3.750 mm (LxWxH) | 11.480 x 6.580 x 4.500 mm (LxWxH) |

| Setup | Table setup | Table and vehicle setup |

| Measuring distances | 1,0 m | |

| Load capacity | up to 10.000 kg | |

| Frequency range | 9 kHz/ 150 kHz to 18 GHz or 40 GHz) | |