EDTC

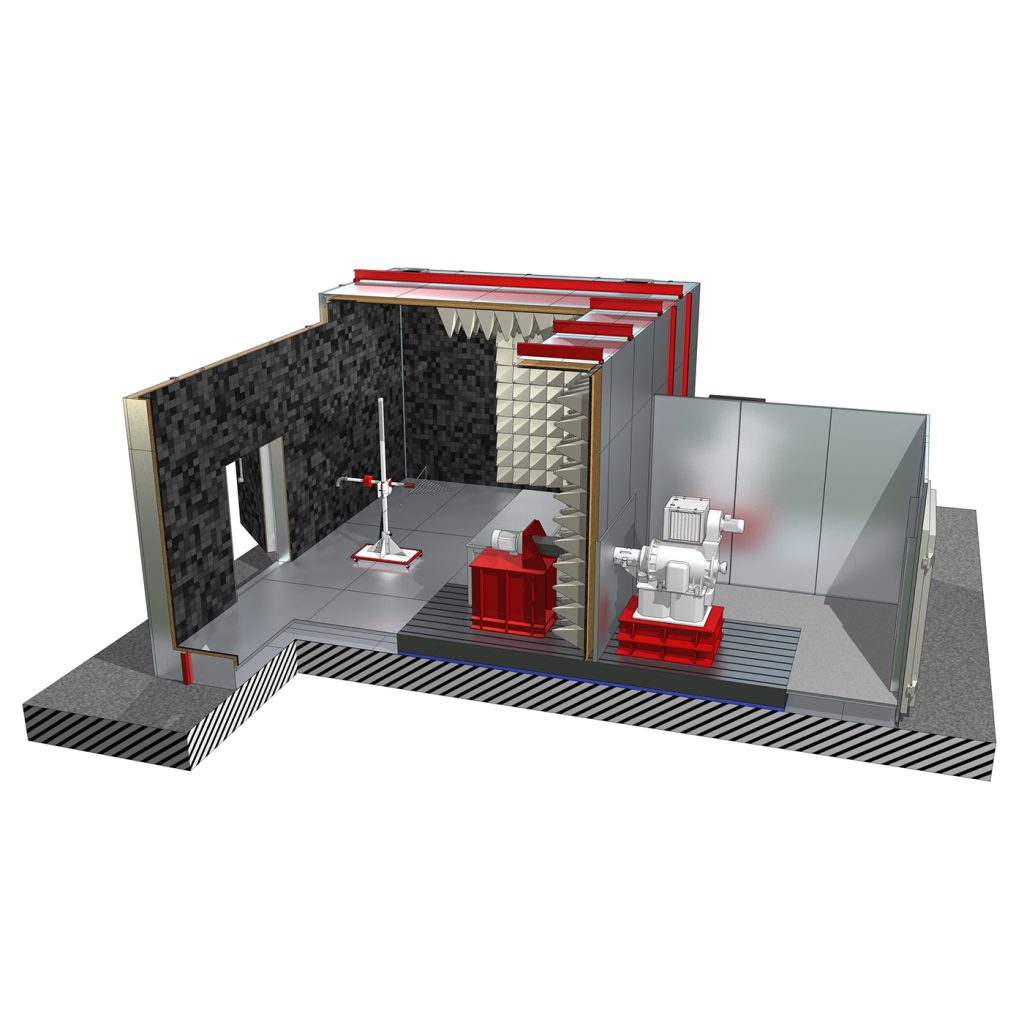

E-Drive Testing Chamber for external load machine

The EDTC is the chamber solution that is specifically prepared for an external load machine with fixed shaft. Similar to the EMC-BlueBox, the system can be used for dynamic EMC tests of electrical powertrain units in a shielded enclosure. It includes, for instance, braking, driving, direction of rotation (right/left), speed regulation, torque control and a mix out of this range.

Alternatively, the EDTC can be equipped with the HYDROS system which is one of the new powertrain setups using a hydraulic system. An external power converter is outside the chamber and produces the oil pressure to the EUT power converter placed inside the chamber.

The EDTC offers superior conditions for radiated emission testing according to CISPR 25 Ed. 4 and radiated immunity testing according to ISO 11452.

| Overview |

| Compliance | CISPR 25, ISO 11452 |

| System | External Load Machine |

| Features | - Fixed System - Useable for motors, components, or in combination with battery tests - Powertrain motor setup or axis setup possible |

| Setup | External shaft for dynamometer outside of EMC chamber, or Hydraulic connectors with external pressure generator |

Features EDTC

Features HYDROS

Absorbers EDTC

Typical Product and Verification Standards

Emission

Immunity

Typical Specifications

| Chamber Type | EDTC |

| External dimensions | 7.880 x 5.480 x 3.750 mm (LxWxH) |

| Setup | Table setup |

| Power range | e.g., 250 kW for single motor setup, or axis setup |

| Test distance | 1,0 m (optional 3,0 m) |

| Load capacity | 5.000 kg (typical) |

| Frequency range | 9 kHz/ 30 MHz to 18 or 40 GHz |